Industry news

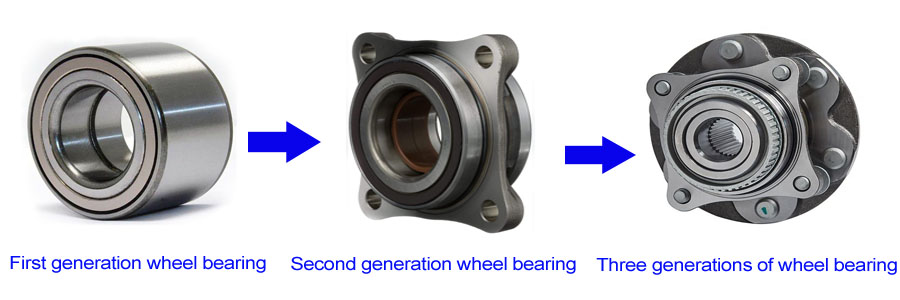

The history of the first, second and third generations of bearing transformation

The first generation of wheel hub bearing

The first generation of wheel hub bearing is double row tapered roller bearing or double row angular contact ball bearings with integral outer ring and back-to-back inner ring combination. In order to ensure that the preload after installation is within the specified range, have to preset initial bearing clearance, and there is no need to use a spacer to adjust the preload on the vehicle assembly line. In addition, the hub bearing has its own sealing ring, which eliminates the manual external installation of the sealing ring.

The second generation of wheel hub bearing

Compared with the first generation, the second generation of wheel hub bearing with flange on the outer ring is characterized by less assembly parts, light weight and convenient installation. The outer ring of the second generation is equipped with a flange plate, which is directly connected to the suspension (inner ring rotation type) through screws, or installed on the brake disc and steel ring (outer ring rotation type).

The third generation of wheel hub bearing

The third generation of wheel hub bearing consists of the outer ring with flange which connected to the suspension and the inner ring with flange which connected to the brake disc and steel ring. Unlike the second generation, the third generation integrates ABS sensors. The third generation generally use swaging technology to self-lock the half inner ring. During the swaging process, axial load is applied to the hub shaft end with flange to deform it to fix the half inner ring. Compared with traditional nut fastening, this swaging technology of hub shaft end has several advantages. For example, the third generation (for non-driving wheels) helps to reduce the volume and weight, also reducing the cost. The load of the third generation (for driving wheel) has been preset before it is assembled into the vehicle, so the step of adjusting the position of internal parts is eliminated. The third generation with swaging technology has the above advantages whether it is used for driving wheel or non-driving wheel.

RELATED NEWS

CATEGORIES

LATEST NEWS

CONTACT US

Contact: ULB BEARING

Phone: 13735493564

E-mail: sales@ulb-bearing.com

Whatsapp:8613735493564

Add: Xiaoshan Economic and Technological Development Zone, Hangzhou, Zhejiang, China.